What if a passive RFID tag, a tag with no batteries or other power source other than the energy harvested from the tag reader, could tell us more about the environment it is located in? This is now possible with the expanding availability of passive UHF RFID sensor tags. These tags detect changes in their surroundings and then transmit that sensor data back to the reader during a tag interrogation. Some off-the-shelf RFID sensor tag examples include temperature, moisture, and strain with the sensor built into the tag’s IC chip. Other RFID sensor tags can record conditions from off-chip sensor technology attached to the sensor capable tag. Some current vendors of RFID sensor IC chips include:

- RHOM Group

- Asygn

- Axzon

It is important to understand passive sensor RFID tags are not data loggers. They only report back the sensed condition at the moment they are being read. These tags have no means to store measured values over time or maintain historical data. For constant or periodic reporting for a sensor, either a hard wired or battery powered system would be a better choice.

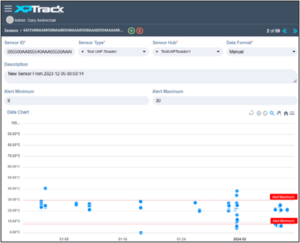

However, if you need to know the current temperature of a group of items and you can routinely read those item’s RFID tags, a UHF RFID sensor tag might work for you. In this case, the system behind the RFID reader becomes the data logger.

This approach places most of the temperature monitoring cost on durable infrastructure and a lowest possible cost on the item itself. Implemented correctly, you get disposable, single use temperature logging that is capable of real time cloud-based reporting.

Implemented correctly, you get disposable, single use temperature logging that is capable of real time cloud-based reporting.

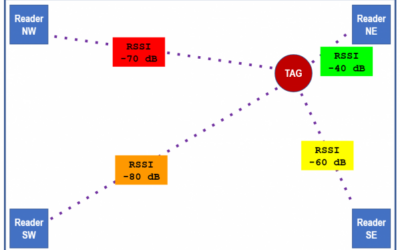

Let’s look at an example in action. Suppose you wanted to monitor the temperature of fresh produce from farm to supermarket. Temperature sensor RFID tags can be applied to the boxes that transport the produce. Readings for each box can be taken consistently while in transport, from the loading dock to the trucks, to storage facilities–all using fixed mount or handheld RFID readers. The added cost for this is only one disposable, single-use, temperature sensing RFID tag applied to each box. What stitches this cost affordable, RFID enabled cold chain monitoring together is a back-end system that provides monitoring of sensor data and more importantly alerts for when information is out of bounds.

Sensor-enabled UHF RFID tags are gaining acceptance into supply chains and other applications where low cost environmental condidtion monitoring enables increased safety, waste reduction, or other quantifiable benefits that more costly data loggers can’t provide. When the technology becomes more prevalent, it will help assure everyone that items moved to your table are as fresh as possible.

0 Comments